七月,南通迪賽主機缸蓋修理創(chuàng)新高

發(fā)布時間:

2023-08-08

DMtech Set a New Record of ME cylinder Covers Reconditioning Numbers in July

盛夏七月,如火如荼。

南通迪賽生產(chǎn)車間繁忙有序,主機缸蓋修理創(chuàng)新單月最高紀錄。分別來自修船廠,如中遠南通船務(wù),南通瑞泰船務(wù),舟山華豐船廠,舟山長宏國際,江陰澄西船廠等。還有來自港口碼頭,如南通通海集裝箱碼頭,連云港新路橋碼頭和上海外高橋二期等。其中船廠工程有兩條船6缸全部翻新。

七月主機缸蓋翻新中,機型B&W50MC/ME占70%。50MC缸蓋吊缸拆解后修理項目,主要集中在密封槽腐蝕、閥座裝配密封面腐蝕,也有部分缸蓋出現(xiàn)油槍孔吹蝕及裂紋,示功孔、啟動閥孔裂紋等。這些問題在50MC主機缸蓋中較為常見。在此重點解析一下B&W50MC/ME缸蓋翻新中碰到的幾個特別案例,共同學(xué)習(xí)和探討。

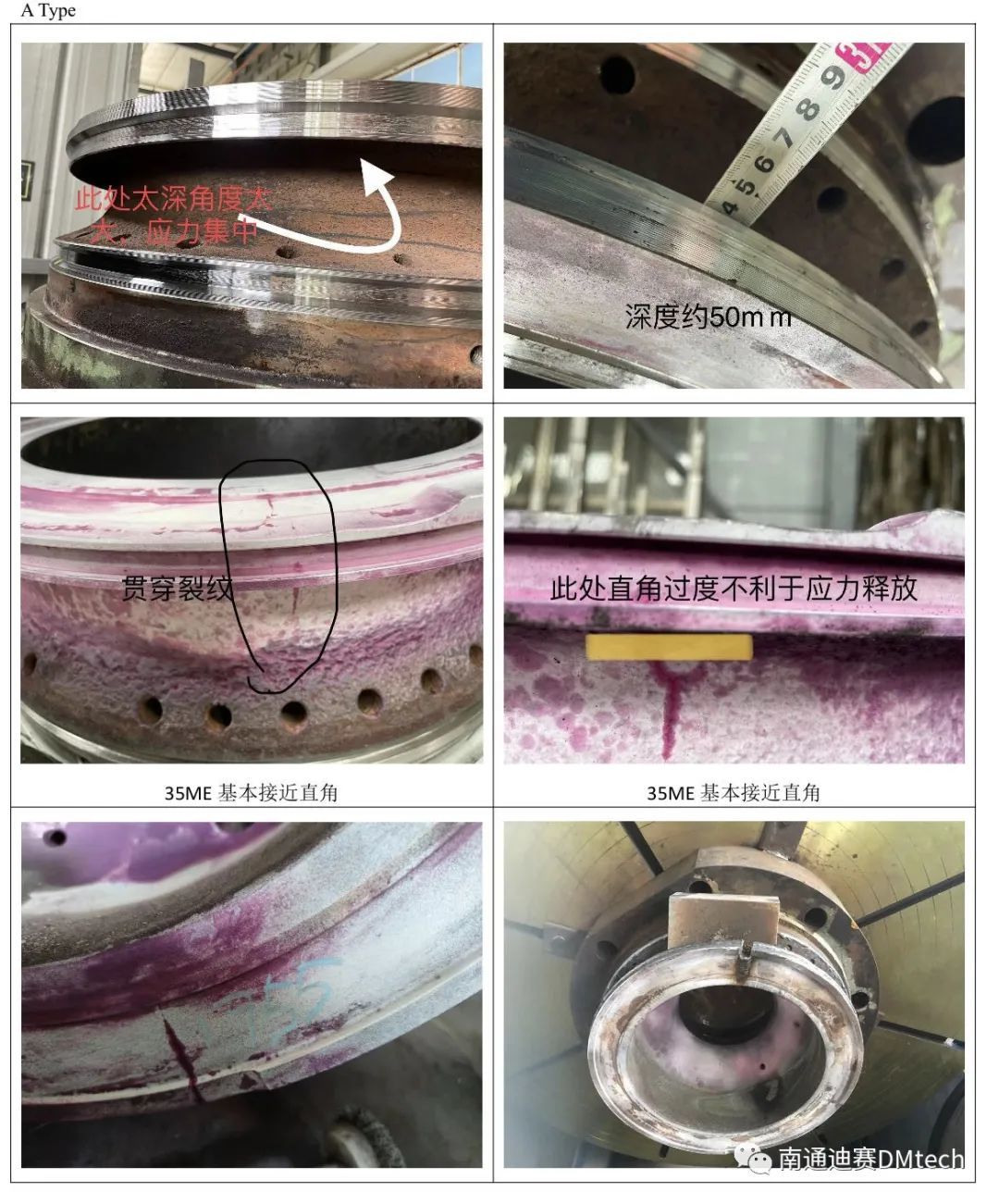

案例一:如圖某船下來一只缸蓋,其他部位狀況較好,主要是油槍孔裂紋,應(yīng)該是裝機使用時間不長。

原因分析:1、油槍孔產(chǎn)生裂紋,一般由于高溫燃燒,在噴油器噴油方向成規(guī)則吹蝕,繼而在孔邊開始出現(xiàn)裂紋,并向孔內(nèi)和孔外延伸。2、此缸蓋裂紋比較特殊,仔細觀察發(fā)現(xiàn),裂紋不是從油槍孔邊緣往上延伸,而是直接出現(xiàn)在之前堆焊的耐蝕合金部位。由此判斷,此裂紋的發(fā)生應(yīng)該與上次翻新廠家燒焊質(zhì)量相關(guān)。手工碳刨后,發(fā)現(xiàn)不熔合現(xiàn)象,焊層中有夾渣,高溫之后,內(nèi)部產(chǎn)生裂紋并延伸到表面。

針對此情況,我們組織焊工現(xiàn)場學(xué)習(xí),并由資深焊接專家傳授經(jīng)驗,分析為什么會產(chǎn)生此類情況及如何避免。

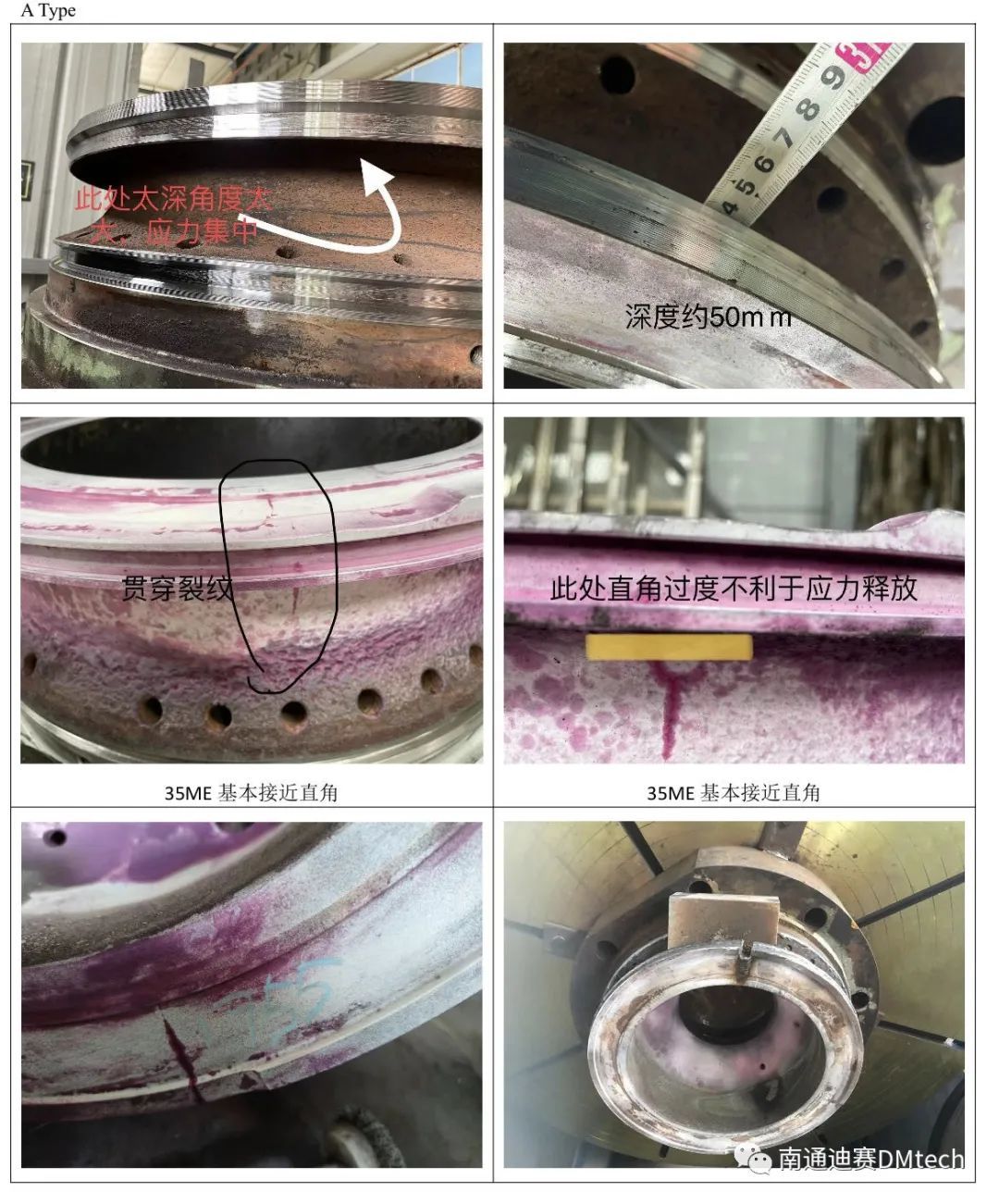

案例二:翻新過程中也經(jīng)常碰到在密封槽和密封面處出現(xiàn)貫穿裂紋現(xiàn)象。這次有一條船的缸蓋出現(xiàn)此類情況。南通迪賽曾經(jīng)承修過這條船的姐妹船,其缸蓋也多次出現(xiàn)貫穿裂紋。許多機務(wù)和老軌經(jīng)常有疑惑,為什么會出現(xiàn)這種貫穿裂紋。船東公司也懷疑是否為保養(yǎng)和管理的問題。

原因分析:經(jīng)過長期觀察和總結(jié),我們認為出現(xiàn)貫穿裂紋的缸蓋多為設(shè)計上的缺陷導(dǎo)致。主要是冷卻水槽過深,過渡角度太小,接近90度。導(dǎo)致應(yīng)力集中,從而容易在此位置最先出現(xiàn)裂紋。對比相同機型,有的設(shè)計過渡角度明顯大得多,基本上未發(fā)現(xiàn)過些類貫穿裂紋。如下圖TypeA很容易導(dǎo)致貫穿裂紋,TypeB有所改進,TypeC則是明顯改進,已經(jīng)基本上看不到角度了。B&W35MC/ME也有類似情況,我們曾按照船東要求,對其進行了改型處理,后續(xù)使用效果正在觀察中。此次有國外船東提出改型要求,我們將持續(xù)跟蹤使用狀況。

修理經(jīng)驗總結(jié):

1、B&W50MC/MC-C/ME雖同為50機型,但是因為高度、外型、及其他關(guān)鍵尺寸的差異,需要在預(yù)檢時就進行仔細比對,既要參考原始圖紙,但是又不能拘泥于圖紙數(shù)據(jù),還需根據(jù)所修工件進行不同應(yīng)對。

2、此次集中修理的50缸徑缸蓋,分屬8條船,適用6張圖紙,對工藝和生產(chǎn)提出嚴峻考驗。我們生產(chǎn)人員本著“我嚴謹、您放心”的一貫作風(fēng),一絲不茍地分析分類,冷靜細致地判斷比對,確保加工尺寸精確,確保修理工藝到位,確保裝機試機一次成功。

3、缸蓋的集中修理,也給我們創(chuàng)造了一個轉(zhuǎn)變生產(chǎn)思路的機會,結(jié)合實際,轉(zhuǎn)變生產(chǎn)模式,把單件修理轉(zhuǎn)變成批量生產(chǎn),提高了效率,增強了工效,滿足了船東對交付工期的要求,得到船東的認可和稱贊。

特別感謝船東、船廠的信任,我們將一如繼往地堅持“我嚴謹、您放心”,質(zhì)量事故零容忍,誠信服務(wù)貫始終,不斷提高服務(wù)船東的能力。

DMtech Set a New Record of ME cylinder Covers Reconditioning Numbers in July

July is always a busy month for shipyard. DMtech also made a new record of ME cylinder covers reconditioning numbers in this month.

Most of them are from shipyards, for example Cosco Nantong, Nantong Ruitai, Nantong Rongshen, Zhoushan HuaFeng, Zhoushan Changhong and Jiangyin Chengxi Shipyard, some of them from the port as Nantong Tonghai Container Terminal, Port of Liangyungang & Port of Shanghai Waigaoqiao.

The 70% cylinder covers are B&W50MC/MC-C/ME type. For B&W 50MC/ME type cylinder covers, the reconditioning items usually are sealing grooves,landing face, pocket for Exh V seat, fuel injector holes , indicator hole, starting valve pocket.

Here we analysis some special cases.

Case 1--The technician found one cylinder cover, the cracks around the fuel injector is not normal. The cracks is on the sector of anti-corrosive material area. Usually the crack is coming from the edge of fuel injector hole. DMtech technician judged it probably was caused by welding. It’s right, the cracks inside the welding lay was found after handing gorging. There are slags inside as last reconditioning, it means the welding quality leads to the cracks.

Case 2--We always find through cracks on the sealing grooves and landing face. The through cracks caused leakage in the sealing grooves. The shipowners would like to think it’s management and maintain problem. We do not think so. Our opinion is the design defect leads to the cracks. We find the angle under the landing face is too small, sometime almost 90 degrees, where the casting stress can not be released properly.

Below Type A always finding cracks. Type B is modified and better than Type A. Type C improves obviously.

The point is cracks should be cleared thoroughly and the annealing must be carried out to release the welding stress. It is very important for qualified reconditioning and to get a longer service life.

We may modify the shape of the cooling water chamber, to make a bigger angle to avoid the centralized stress, according to owner’s request.

There are many type of B&W 50MC/ME cylinder covers, because of the difference of total height, the out-shape, the sealing grooves and fuel injector dimension. The 50MC/ME cylinder covers came from 8 vessels and met to 6 drawings this month. The inspector should be very careful to get the dimension and submit the sketch to latheman. Anyway most of DMtech technicians have been working in the reconditioning industry more than 15 years, they know why profoundly and know how perfectly.

Hot July and lot orders did not delay our delivery. So passionate a July!

相關(guān)新聞

掃描訪問手機版

南通迪賽船舶科技有限公司

地址:江蘇省南通市崇川區(qū)興盛路129號

聯(lián)系人:成國榮 余立剛

手機:0086-13776909006 15370660922

Email:sales@dmtechnantong.com

電話:0086-513-85252179/85252169

傳真:0086-513-85252169

Copyright ? 2022 南通迪賽船舶科技有限公司